The storage enclosures housing your data may determine how much drive vibration interferes with application performance. Since we understand our hard drives better than anyone, we designed storage enclosures that can dramatically reduce vibration.

Walk into any data center and you’ll see them, rack after rack of metal enclosures, many with lights on the front, all with cables out the back, their fans and power supplies driving energy in and heat out. Inside, a variety of technologies powering data workloads, depending on function.

These enclosures are the true workhorses of the data center, but until recently, most of the attention was paid to the technology inside the boxes – from hard drive and SSD innovations to CPUs and memory. Of course, storage boxes go by many names – servers, storage shelves, JBOFs, JBODs, arrays – but with so much focus on the inside, little attention has been paid to the technology of the enclosure itself.

I’d like to change that.

At Western Digital, we have what is arguably the broadest storage portfolio of any company.

New Enclosure Engineering Using Silicon to Systems Design

At Western Digital, we have what is arguably the broadest storage portfolio of any company. We make everything from silicon to systems: we manufacture the raw NAND in our fab for our SSD products; we make the heads and disks that are the fundamental technology for our HDDs; we also make primary hybrid and all-flash storage systems and rack-scale object storage systemscomplete with software and services.

Because of our breadth of offerings, we have a unique understanding of how each part of the system is influenced by, and influences other parts of the entire stack. We use this knowledge to improve everything including performance, capacity, endurance, quality and reliability. We call this holistic approach to engineering Silicon to Systems Design.

Starting storage server design from the ground up allowed us to rethink a few design elements through the intimate knowledge of our drive technology. It was natural to bring Silicon to Systems Design to our storage enclosures and we ended up with multiple innovations. I’d like to look at one of those today – IsoVibe™.

Why Drive Vibration Control Is Important

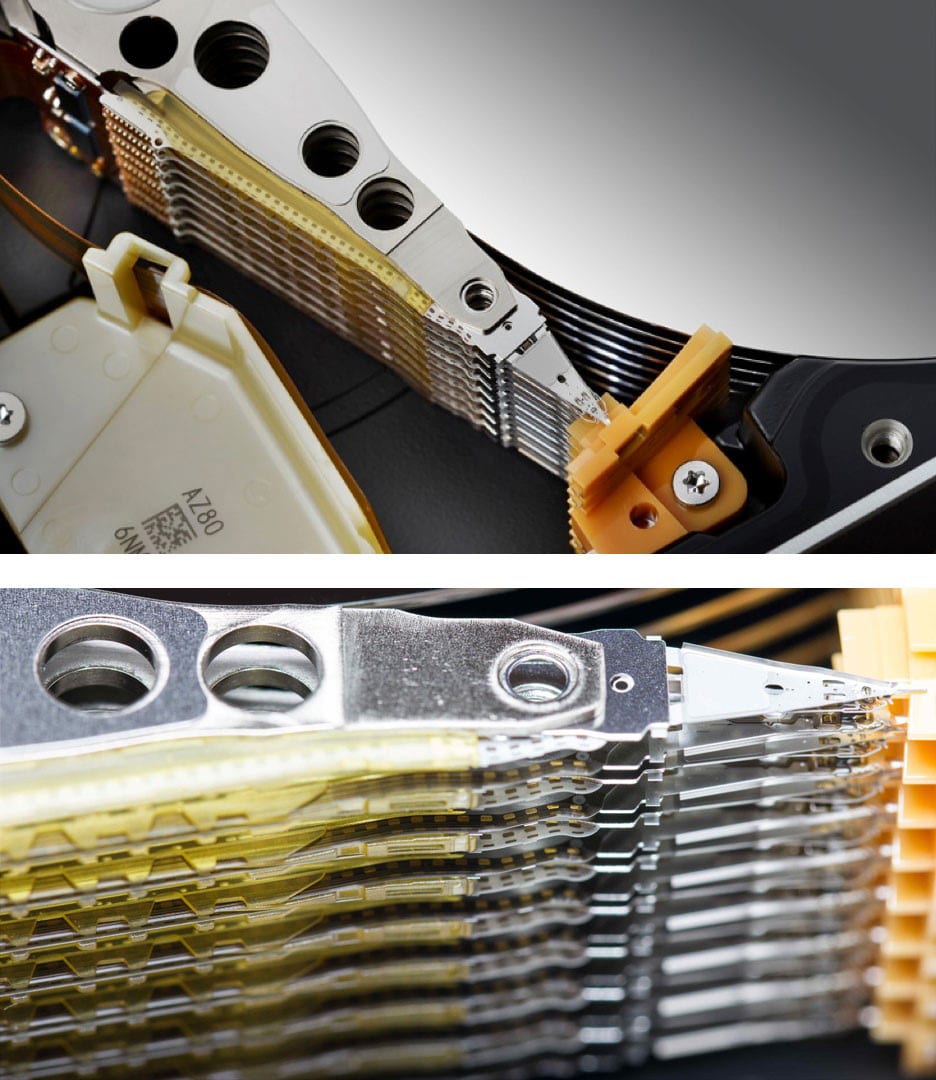

Vibration is a real challenge for spinning media. Despite very sophisticated servo mechanisms in the drives, external shock and vibration can cause the head to take longer to settle onto the track and can even cause the head to go off track. What this means for the data center is latency and slower performance of applications as the head has to resettle and wait for the correct sector to come around again.

In a dense array of disk drives, adjacent drives that are seeking at high speed can induce vibration into their neighbors. Fans, too, create vibration through the chassis and also through the air as sound energy.

Innovations in high capacity disk drives depend on scientific advancements from many fields to create the outright magic that occurs inside (you can read about some of the amazing technologies under the hood). These drives need to squeeze ever-tighter track density onto magnetic platters, which means extremely tight tolerances on positioning the read/write head correctly to follow the data track.

Drive vibration control in storage enclosures is more critical than ever.

Introducing IsoVibe

Because we understand the interaction of the internal servo systems that position the heads over the track with the outside world, we were able to design precise vibration isolation into the baseboard that supports the drives. We also paid attention to vibration isolation of the transmitted interference and acoustic vibration of fans that are also a source of irritation to hard working HDDs.

IsoVibe reduces vibration of individual drives by up to 63% compared to traditional enclosures. Also, testing against another competitor enclosure showed head positioning total run out (a key measure of how a read/write head stays on track) reduced by 24%.

What that means for you is technologies that help maintain performance across the enclosure, contribute to long-term quality and reliability. They will also enable us to extend storage capacities in the future. That means we can deliver future dense enclosures that continue to meet the performance, capacity and reliability needs of your workloads.

Learn More

Did I get you excited about storage enclosures? You can read more about IsoVibe technology here, see our portfolio of storage platforms here, and learn how customers are benefiting from Silicon to Systems design.

Watch out for the next part of this blog where we’ll explore more technology driven by Silicon to Systems Design. And in the meantime, when you next walk into your data center, spare a thought for those hard-working enclosures.