Purposeful Progress: Driving Towards the Future with Customer-Centric Innovation

Key takeaways

- WD’s customer-centric innovation prioritizes five enterprise storage needs: capacity, reliability, performance, power consumption, and total cost of ownership (TCO).

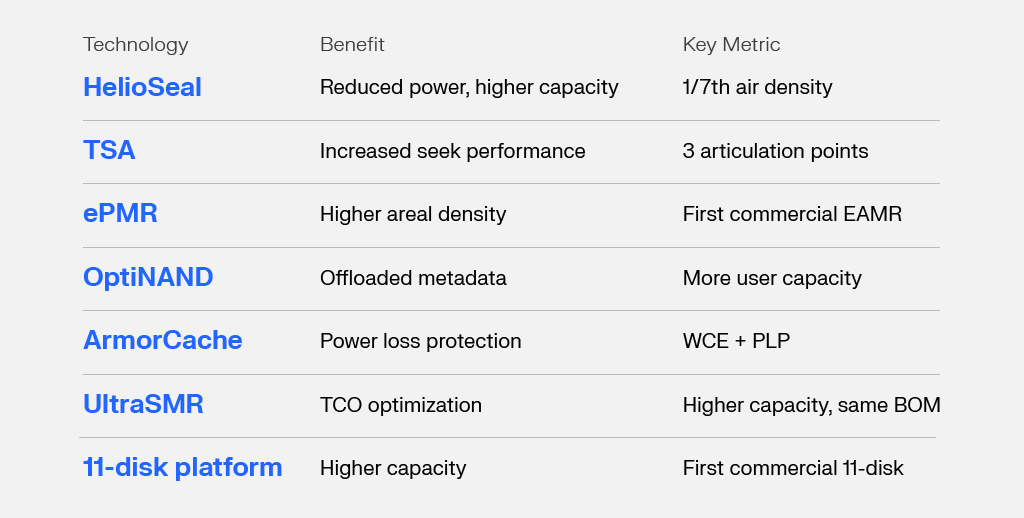

- Core innovations like HelioSeal® (helium-filled drives), the triple stage actuator (TSA), OptiNAND™, ArmorCache™, and UltraSMR extend PMR capacity while de-risking the transition to HAMR.

- HAMR technology will deliver huge capacities, with optimal TCO achieved when capacity gains outweigh early manufacturing costs at 40TB and beyond.

- WD’s 55-year legacy includes 4,500+ active patents and 300+ PhDs driving HDD innovation and powering hyperscale data centers.

- Every technology advancement undergoes rigorous qualification to ensure seamless deployment, reflecting CPO Ahmed Shihab’s philosophy: “We always deliver what we say we’ll deliver.”

In the world of technology, the choice is simple: you innovate, or you get left behind. But the key is that innovation is not done merely for innovation’s sake—it must be tied to satisfying customer needs. Whether that’s iterating on products to address an issue that customers have identified themselves or creating new products or features to solve problems that customers may not have realized they had, innovation must be customer-centric to be useful.

WD and the modern HDD

Though first invented in 1956, HDDs are not an “old” technology. In fact, modern HDDs have evolved to incorporate some of the most cutting-edge technology in existence. Each new generation of HDDs incorporates advancements that drive capacity, performance, and reliability to new levels.

WD has a rich 55-year history of industry firsts in this field. In the early years, that innovation wasn’t yet related to hard disk drives. 55 years from now, we plan to still be pushing boundaries in the technologies of the future. We currently hold over 4,500 active patents and employ over 300 PhD holders in the fields of engineering and sciences. With each innovation, we reinvent the limits of what’s possible.

But as we embark on the next big technologies, including heat-assisted magnetic recording (HAMR), it’s worth remembering exactly what drives our technology philosophy: customer-centric innovation.

Our two rules of customer-centric innovation

The ultimate measure of technology isn’t how many whiz-bang features and breakthroughs it contains—it’s what it does. Our customers are technologically savvy and are keen to track our technology roadmap, but they all understand that the technology is in service to their business models. Customers have specific needs when it comes to storage: capacity, reliability, performance, power consumption, and total cost of ownership (TCO). That last metric, TCO, is critical, and the other four can significantly factor into the TCO equation.

While it might be glib to suggest that we could bring our customers a “storage box full of magic” as long as it meets their needs in those key areas, I think of HDD technology as satisfying Arthur C. Clarke’s Third Law: “Any sufficiently advanced technology is indistinguishable from magic,” and that describes the technology within a modern HDD. Regardless of what magic our scientists and engineers invent, our first rule of customer-centric innovation is that every single advancement must serve those core customer needs. If it doesn’t, our customers won’t care how magical it might seem.

Our second rule for customer-centric innovation is that it must deliver improvements while minimizing risk. Our customers are betting their very businesses on our technology. HDD storage is indispensable infrastructure, a critical pillar of the modern data center, and infrastructure simply has to work. We cannot roll the dice with our customers’ business futures on unproven or immature technology. We have to approach every technology shift in a way that de-risks our customers’ ability to deploy new products. While every technological innovation—also often known as invention—initially stretches beyond the bounds of the possible into the unknown, it must be approached in a way that customers can trust will work as advertised.

WD has proven over many years that we introduce new products, new capacities, and new features with careful planning and meticulous execution so that our customers can rest assured they’ll work. As WD Chief Product Officer Ahmed Shihab said in an interview in July 2025, “We’re not flamboyant. We always deliver what we say we’ll deliver.” Introducing new technology while minimizing qualification and deployment risk is at the core of WD’s philosophy.

“We’re not flamboyant. We always deliver what we say we’ll deliver.”

– WD Chief Product Officer Ahmed Shihab

WD core innovations

Over the past decade+, WD has pioneered key HDD innovations. These were built upon learnings from working closely with customers and delivered in a way that could be quickly qualified and deployed at scale.

- HelioSeal®: Helium-filled HDDs are not a recent invention; WD first started shipping HelioSeal drives in 2013. But helium is one of the key foundational technology advances to high-capacity storage. Helium, at 1/7th the density of air, reduces drag and allows for HDDs to contain additional internal disks, reducing power consumption and improving reliability.

- Triple stage actuator (TSA): In an HDD, the ability to reliably read and write data is contingent on the actuator’s ability to fly a very tiny head over an impossibly narrow track. For generations, HDDs only had a single pivot driving the actuator. With TSA, WD adds two additional articulation points in the actuator. Having three independent articulation points allows for greater bandwidth when track-following, increased seek performance, and higher capacity by enabling narrower track width.

- ePMR: Energy-assisted perpendicular magnetic recording, or ePMR, was a key learning during WD’s exploration of microwave-assisted magnetic recording (MAMR) technology. With the release of the Ultrastar DC HC550 HDD, ePMR became the world’s first commercially deployed energy-assisted magnetic recording (EAMR) technology. ePMR stabilizes the magnetic write field, reducing jitter when writing to the disk, which in turn enables higher areal density.

- OptiNAND™: Innovation doesn’t begin—or end—at the head and media; it’s “thinking outside the disk.” OptiNAND enhances drive capacity by offloading certain metadata that previously existed on disk to an external flash component. This move of metadata leads directly to additional user capacity on the disk, and also provides additional margin that allows for decreased track width, boosting areal density even further. On top of this, OptiNAND is a key enabler for our next two breakthroughs …

- ArmorCache™: For decades, HDD users were forced to choose either write cache enabled (WCE) or write cache disabled (WCD) operation, a tradeoff of performance vs power loss data protection. ArmorCache, enabled by OptiNAND, eliminates this compromise by providing a fast flash offload capability upon unexpected power loss. While the system must still choose WCE or WCD, customers operating in WCE mode enjoy full enterprise power loss protection (PLP), while those operating in WCD mode enjoy equivalent performance available to WCE mode. Critically, no software changes are needed from the host to take advantage of ArmorCache—it’s truly the best of both worlds.

- UltraSMR: The TCO advantage of SMR is simple: higher capacity within the same physical 3.5” HDD device, the same power consumption, and the same bill of materials. UltraSMR, an enhancement of traditional SMR, incorporates novel data-encoding and error-correcting techniques, allowing for a much more significant capacity increase over CMR hard drives. This additional capacity increase results in more compelling TCO and faster time to value.

- 11-disk mechanical platform: With the Ultrastar HC590 and HC690 products, WD introduced the world’s first 11-disk 3.5” HDDs on the market, offering an immediate 10% capacity advantage over 10-disk architectures. This mechanical platform was designed with customer shock and vibration guidelines in mind, allowing this new generation of drives to be quickly qualified and seamlessly deployed among WD’s hyperscaler customers.

What ties all of these innovations together is that they addressed several of the key needs facing our customers. The predictable and purposeful introductions allowed for frictionless qualification and accelerated deployment timelines. While the list above is not all-inclusive, it represents key areas where WD did something big, first, and successfully—and all aligned to our customers’ needs.

The HAMR future: Our path to huge HDD capacities, optimized TCO

It’s no secret that HAMR will be a next big leap forward in HDD storage technology. While we’ve taken the areal density of traditional PMR far beyond expectations, achieving capacities today of 26TB in CMR and 32TB in UltraSMR, it’s time to take that next step. HAMR is a complex and challenging technology, and to achieve its promise, it must satisfy core requirements. Critically, cost and reliability are two customer needs that HAMR technology stresses.

HAMR adds bill of material (BOM) cost to the drive. As a new technology, initial manufacturing yields may be lower than established technologies. This impacts TCO given that any capacity gains must overcome the early pressures of added cost and lower yields to be worthwhile. Reliability is another lever. The ability to make the lasers in the drives’ write heads last and achieve the MTBF and workload ratings that our customers expect is non-negotiable. Given this equation, we believe that the optimal TCO and reliability inflection point will be achieved in the 40TB-and-above capacity range.

How WD de-risks the HAMR transition

Many of WD’s earlier breakthroughs listed above provided a key extension to PMR, the known and trusted recording technology, while also providing a bridge to HAMR. Our fidelity to customer-centric innovation has meant enhancing our ePMR products by extending their capacity, reliability, and TCO benefits while building a strong and capable transition to HAMR adoption.

But those technologies are not limited to merely bridging the gap. Capacity-enabling advancements like HelioSeal, TSA, OptiNAND, UltraSMR, and the 11-disk mechanical platform will carry forward into WD’s introduction of HAMR, allowing us to further maximize the areal density gains that HAMR enables. These core innovations, being fully mature, reduce the risk of the HAMR transition, as we focus on the key head/media design as only a single layered change upon a robust platform already built. HAMR is the next step, but it’s a smaller step when so much of the key bridging work is already completed.

Solving the customer data storage needs of the future

Innovation is necessary in the technology space, but it alone is not sufficient. Customer-centricity is the missing ingredient. At WD, we think like our customers to become a better vendor. We understand their applications, their workloads, and their economics. Understanding their qualification timelines, asking questions, and having the ability to ramp HDD volumes to support their deployments keep us in tight alignment. We will also continue to recognize that different customers and different markets have unique storage needs beyond merely capacity. It’s not just about offering higher capacity; it’s about solving all those needs.

In the future, we’ll continue sharing insights on customer collaboration, technology evolution, and advancements in data storage technology. But today, we’re celebrating the 55 years of proven success and the core innovations we’ve brought to market in the recent past. It might seem like a little bit of a victory lap, but it’s just the training that prepares us for the race ahead.