Helium-sealed technology is just one of three essential pillars that support higher track density.

“We have made deliberate and substantial investments in both Damascene and micro-actuation for the past five-plus years to push the limits of areal density.” — Brendan Collins

Western Digital has existing technologies that provide the foundation to support increased TPI.

The data storage industry is undergoing a major shift in which new market segments and storage tiers are emerging, creating high demand for scalable, mass storage at cost-effective prices. The Capacity Enterprise Hard Drive segment is currently experiencing a 40% compound annual growth rate (CAGR) in petabytes stored.

Helium-Sealed Technology

Helium-sealed drives are part of this segment and represent one of the most significant storage technology advancements in decades. Helium-sealed technology hermetically seals the drive housing with inert gas, which provides a less dense atmosphere than air. This lower density not only enables thinner disks to be used, but more of them as well, delivering higher capacities in the same physical form factor

With the understanding that helium-sealing HDDs is a core technology that can keep pace with the value and growth of data, Western Digital invested in, designed, and built a fundamentally sound helium-based hard drive platform much earlier than its competitors, and has delivered continual improvements each generation.

Western Digital is committed to deliver more capacity-enriched helium HDDs in the future, based on proven and successful HelioSeal® technology.

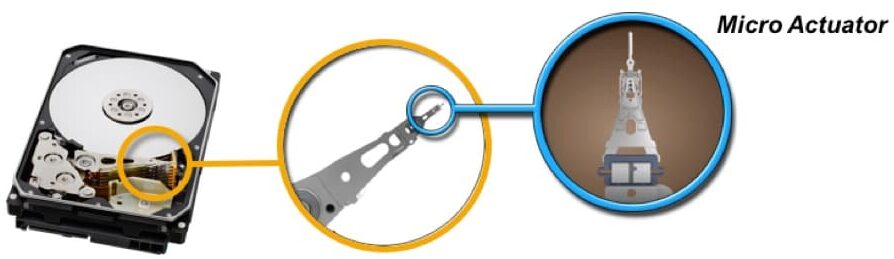

Multi-Stage Micro Actuator

An actuator reads data from or writes data to a magnetic recording disk using a head assembly. As the number of tracks per inch on the disk increases, the finer the control of the head and actuator arm assembly must be to position it over the center of the data track and, as more tracks are packed onto a disk, one actuator becomes inefficient.

To address this challenge, Western Digital was the first to deliver multi-stage micro actuation in its third generation HelioSeal Ultrastar He10 HDD. This micro actuator adds a finer control stage that delivers even greater accuracy of the head assembly over these smaller, narrower tracks. When implemented into Western Digital’s helium HDD portfolio, the micro actuator delivers better performance, data integrity and overall drive reliability versus single stage actuation and supports track densities beyond 400,000 TPI.

As a core hard drive technology, micro actuation has enhanced Western Digital’s helium platform, demonstrating another good technology choice that we made. With the addition of micro actuation, its mechanical head positioning technology is more advanced and better today than the competition, and works well in tandem with the other HDD core technologies.

Damascene Head Process

An HDD head assembly uses a magnetic field to read data from, and write data to, the surface of a magnetic recording disk. Electrical currents flow through a coil in the write head assembly that magnetizes a small area on the storage media, producing the magnetic field, enabling data to be recorded.

When bits are written, they are oriented on the disk by flipping polarity to either a 1 or 0. The bit density is defined two important hard drive parameters; (1) bits per inch (BPI) along the track; and (2) tracks per inch (TPI). Multiplying the BPI by the TPI gives us the disk’s areal density — or how much capacity per square inch is available on the disk’s surface.

The higher the TPI, the more areal density and capacity per square inch that is available. Scaling is limited by the write-ability of the recording system and the track pitch, requiring a reliable, narrow write head, with tighter spacing, to achieve smaller tracks.

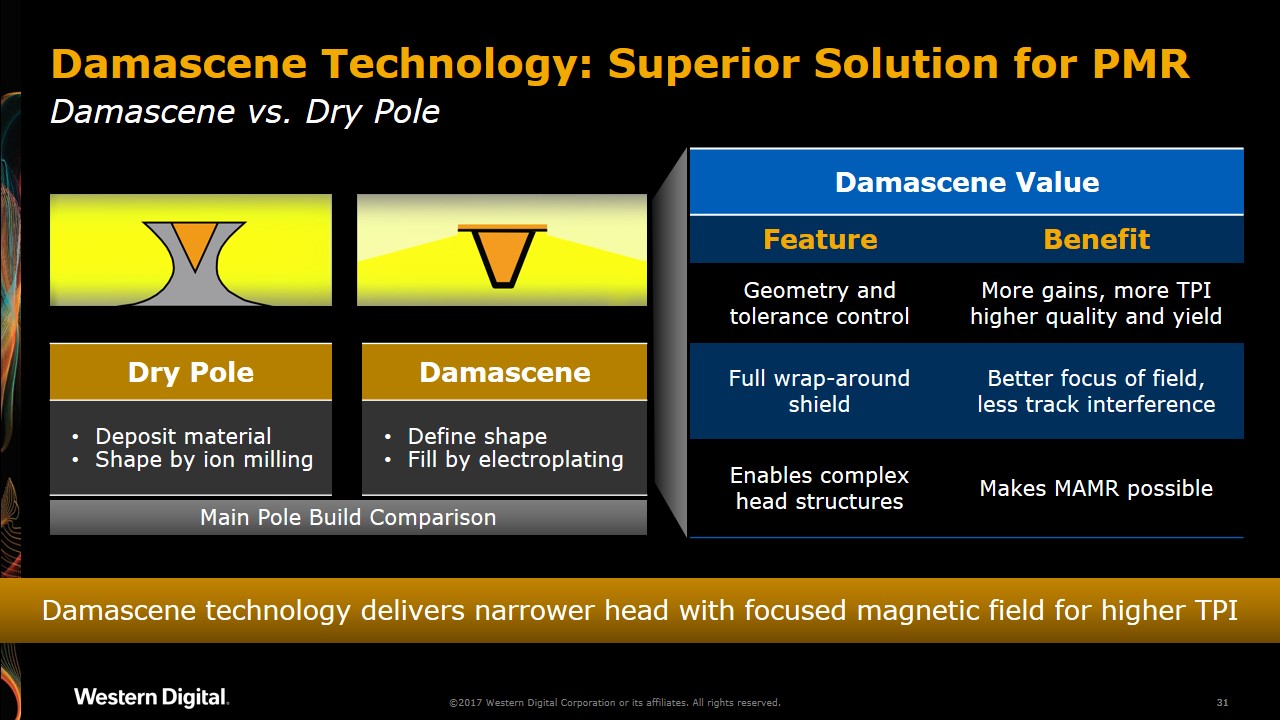

It was at this stage in its history that Western Digital was faced with a critical strategic decision on the direction to take, and investment to be made, in the head manufacturing process, to increase hard drive capacities in the future. As the gains from perpendicular magnetic recording (PMR) were slowing down, the decisions were to either invest substantial dollars in the Damascene head-making process for extending gains in PMR, or rely on large gains and early productization of heat-assisted magnetic recording (HAMR) technology).

Western Digital decided to invest in improving its current hard drive technologies and pursue multiple options for increasing enterprise capacities, versus relying on HAMR technology (as it continued to be challenged with complexity and reliability issues. The decision proved prudent and will lead the way for Western Digital to increase enterprise capacities over the next decade, without HAMR.

From internal testing, heads produced using the Damascene process provided a TPI advantage over the previously-used dry pole process, delivering the highest track density available and superior performance, with improved quality, better head write-ability, and higher head yields. A significant reduction in adjacent track interference (ATI), was also achieved using the Damascene process.

The dry pole process limits innovation that is possible through material and geometry changes. Used in semiconductor design, the Damascene process has many advantages including better control of the head geometry (which affects areal density gains and helps mitigate interference from neighboring tracks), better scaling of the head dimensions (which affects TPI and areal density), and better control of the manufacturing process tolerances (which affects head quality and head yields).

In quick review of the HDD core competencies driven by Western Digital, we pioneered helium-sealed HDD technology — were the first to deliver multi-stage micro actuation for better head positioning in a hard drive — and produced several hard drive innovations using the Damascene head-making process to obtain finer control of the head shape and dimensions when writing to a small, narrow track on disk.

The decision to improve current core HDD technologies, coupled with the successful development and execution of these technologies, position Western Digital as the leader in hard drives today, and we will deliver increased hard drive capacities in the future. However, leveraging existing technologies can only increase capacities to a certain level even when the most innovative platforms are used.