From Floor to Door: Barcodes Are Running Our World

When a baby is born in a hospital, one of the first things they’ll receive is a barcode. It may not be the most poignant gift for the profound experience of birth, but barcodes help ensure a baby is matched to the right mother. They link lab results to a patient’s record. And they are how nearly every single thing on this planet is tracked regardless of industry or sector.

Barcodes have been around for more than half a century. They have become so commonplace, we don’t think about them much. They just do what we expect them to do: instantly identify something—our groceries, the sneaker delivery we’ve been waiting for, or a discount from a customer loyalty program. But behind the scenes of that ubiquitous “beep” is a world of data revolutionizing how companies meet rising consumer demands and challenged supply chains, from the manufacturing floor to our doorstep (and sometimes back again).

Real-time logistics

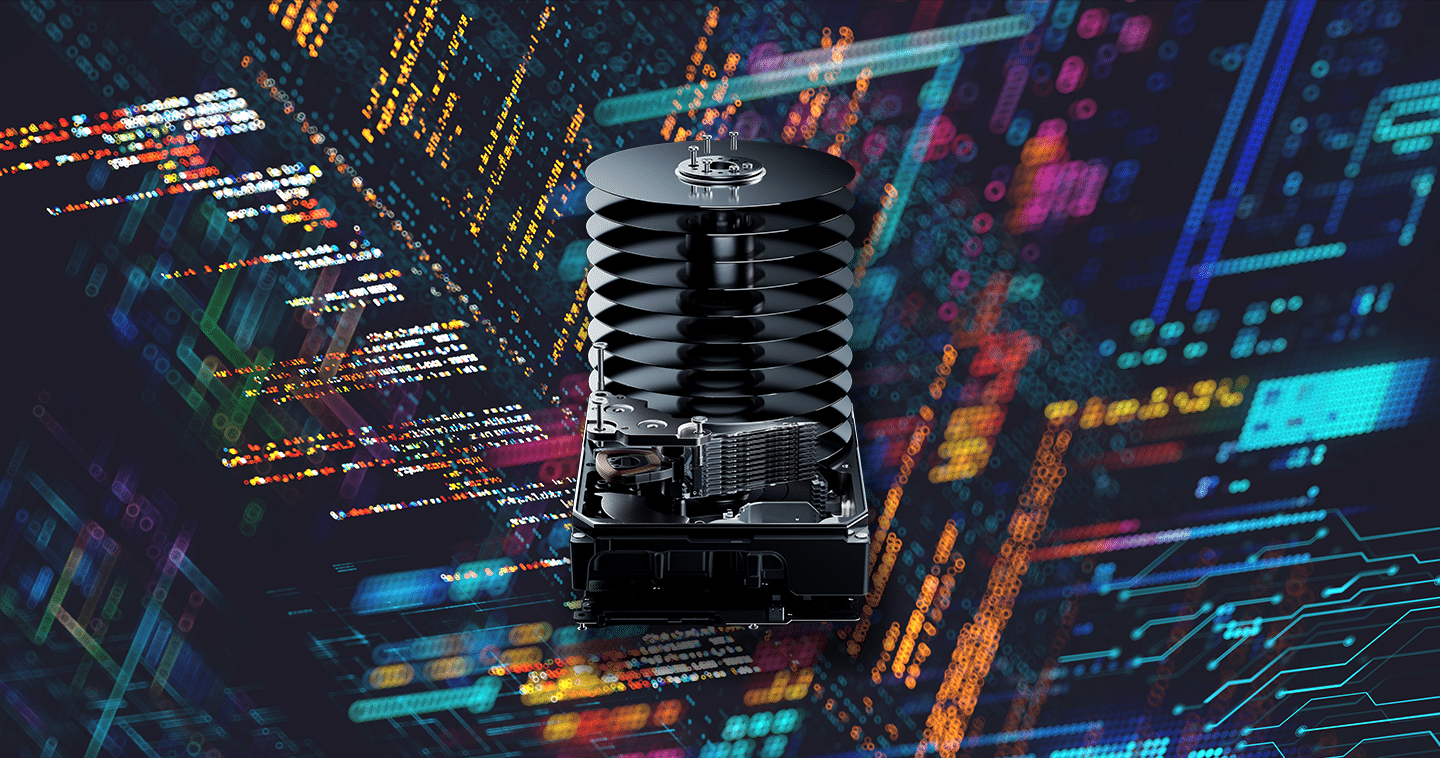

Vamshi Krishna Reddy Mowgili is the program manager and solutions architect at Western Digital’s Logistics Center of Excellence. Mowgili and his team enable new capabilities for the company’s logistics and supply chains. They spend their days on the hunt for disruptive technologies.

Western Digital’s logistics are herculean. The company ships millions of products. These flash storage and hard drive solutions are shipped from multiple countries and are served to thousands of locations worldwide. It’s a frenzied operation. At the heart of it all are the barcodes that track everything.

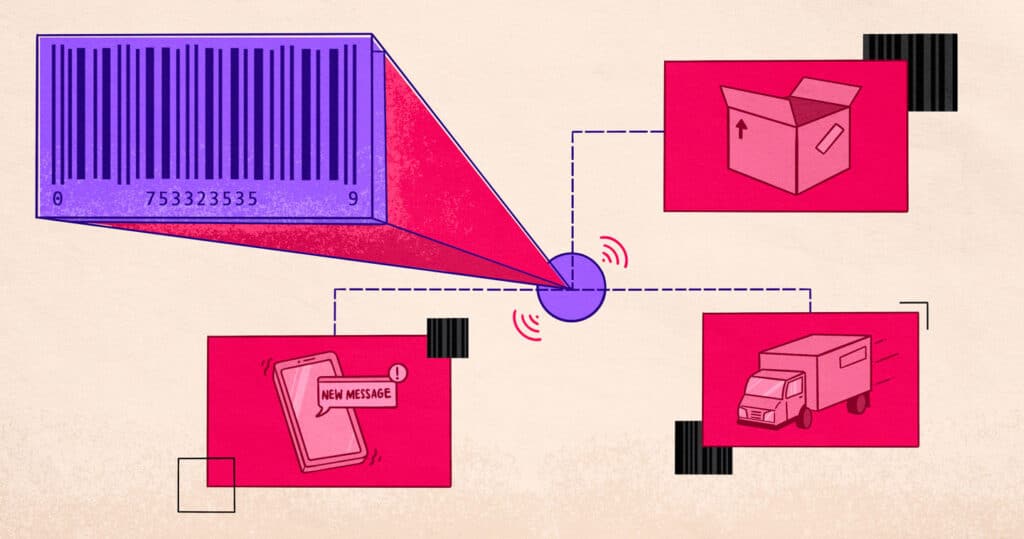

“Barcode scanning is not just about reading the data,” explained Mowgili, “it’s about connecting two systems and transferring the data from one system to another system in real-time.”

A single scan at a manufacturing site can automatically trigger a shipping request, enter a line in financial records, notify a customer, or kick off a complex supply chain of resources and tooling. It’s the entry point to the labyrinth of applications powering sophisticated businesses.

Much of Mowgili’s work is about connecting systems from inside and outside the company’s network to streamline an efficient workflow. “We need to do this with as little human dependence as possible to make sure we get the right data fast,” he said.

Logistics, in particular, has a data challenge. Once products leave the tight control of Western Digital’s manufacturing and warehouses, they travel across the world. This journey can take up to 11 days using multiple carriers and third-party services. The data Western Digital receives from each service uses its own system and offers divergent data points and little control or granularity.

One of the innovative undertakings Mowgili and his team have introduced is incorporating IoT devices that, after scanning a barcode, track real-time information about packages. While we’ve become accustomed to location tracking, these devices offer richer data about altitude, temperature changes, and tampering attempts. Why the need for such intricate details?

One example Mowgili shared was the unraveling of a case in which a large customer received a package with melted products that left the product quality teams baffled. “With these IoT devices, we could find the time and place of a temperature spike. We then extracted that the commercial operator inadvertently loaded goods into the aircraft right behind the exhaust of the jet’s engine,” said Mowgili. “We could pinpoint a single moment in a very complex logistical chain amid thousands of moving pieces.”

The success of this project is emblematic of how Mowgili sees Western Digital empowering its customers. “Being a data storage company, we always talk about helping customers to unlock the potential of the data,” said Mowgili. “This is exactly what we [team] do. It’s not about the device. It’s about generating insights through the simple act of scanning a barcode.”

Tracking everything, everywhere

One of the companies on the receiving end of Western Digital’s logistics is Zebra Technologies Corporation, a company specializing in technology used to sense, analyze, and act in real-time.

Western Digital’s embedded flash storage powers some of Zebra’s suite of barcode scanners, handheld computers, tablets, and printers. But don’t think of this company as a supermarket checkout counter. Zebra is a data powerhouse. The company’s solutions power 86% of the Fortune 500, massive logistics fleets, and some of the largest and most advanced retail operations. The company is even an official partner of the NFL, tracking real-time data on every player and every play on the field.

Matthew Guiste is responsible for Zebra’s global retail technology strategy, a sector fraught with post-pandemic challenges. “The pandemic really forced a number of new behaviors,” said Guiste. “People now want to buy online but pick up their goods from different locations—at the store, curb, a locker, or even a distribution center.”

Some call this the new omnichannel approach. Others term it as “unified commerce” or even “phygital,” the mix between a retailer’s digital and physical experience. But regardless of how you dub it, Guiste explains this transition happened so fast that these systems aren’t very efficient.

“The pandemic put rocket fuel on the pace of these changes, compressing what could have taken a decade to be done in just a few years,” said Guiste. “Retailers were forced to change because they couldn’t stay open or didn’t have their normal mechanisms to be able to conduct transactions. But if you look at the margin on a transaction that goes through one of those alternate channels, it’s several points less profitable because the systems are not set up from start to finish to be able to enable that efficiently.”

Guiste acknowledges that making that phygital experience frictionless is no small feat, especially when managing inventory. “The increase in the volume of activity, number of items, and all the different ways they can get moved into or around the store itself have made keeping real-time track of inventory the number one challenge.”

According to Zebra’s Annual Global Shopper Study, nearly half of the shoppers that left a store without the item they wanted left because it was out of stock. It’s a 26% increase since pre-pandemic times. The unpredictability of supply chains and etiquettes like bracketing and easy returns exacerbate inventory woes. “A retailer’s duty is to make the return process as flawless as possible for the consumer, but it’s incredibly expensive when inventory isn’t managed efficiently,” said Guiste.

Working with retailers across the globe, Guiste and the teams at Zebra are helping “track everything, everywhere,” said Guiste. “Everything is real-time inventory all the time—in the supply chain, in the backroom, and in the front of the house.”

It’s why you’ll see more and more workers in stores carrying tablets, handheld computers, or even wearable ones. Actionable insights about inventory need to be available to all decision-makers, whether the CEO or an associate on the shop floor.

“Barcodes give us a digital view of the physical world,” said Guiste. “What we’re helping companies do is use them to get real-time operational visibility from the floor to the door—from manufacturing all the way to the consumers’ home.”

The little barcode that could

Barcodes have been an integral part of the global economy for decades. The introduction of more complex barcodes (such as the airline industry’s Aztec barcode and QR codes) has increased the possibilities of what can be tracked and how. For companies like Western Digital and Zebra Technologies, these are opportunities to create real-time logistics, garner actionable insight, and bridge the gap between digital and physical experiences.

The more items become connected, traceable, and trackable, the more transparent the supply chain. It’s an opportunity to drive a more sustainable and circular economy.

“Barcodes are rapid and easy to scale and implement,” said Mowgili of Western Digital. “But it’s not about the technology itself; it’s about how you’re going to use technologies to solve problems and make a difference.”